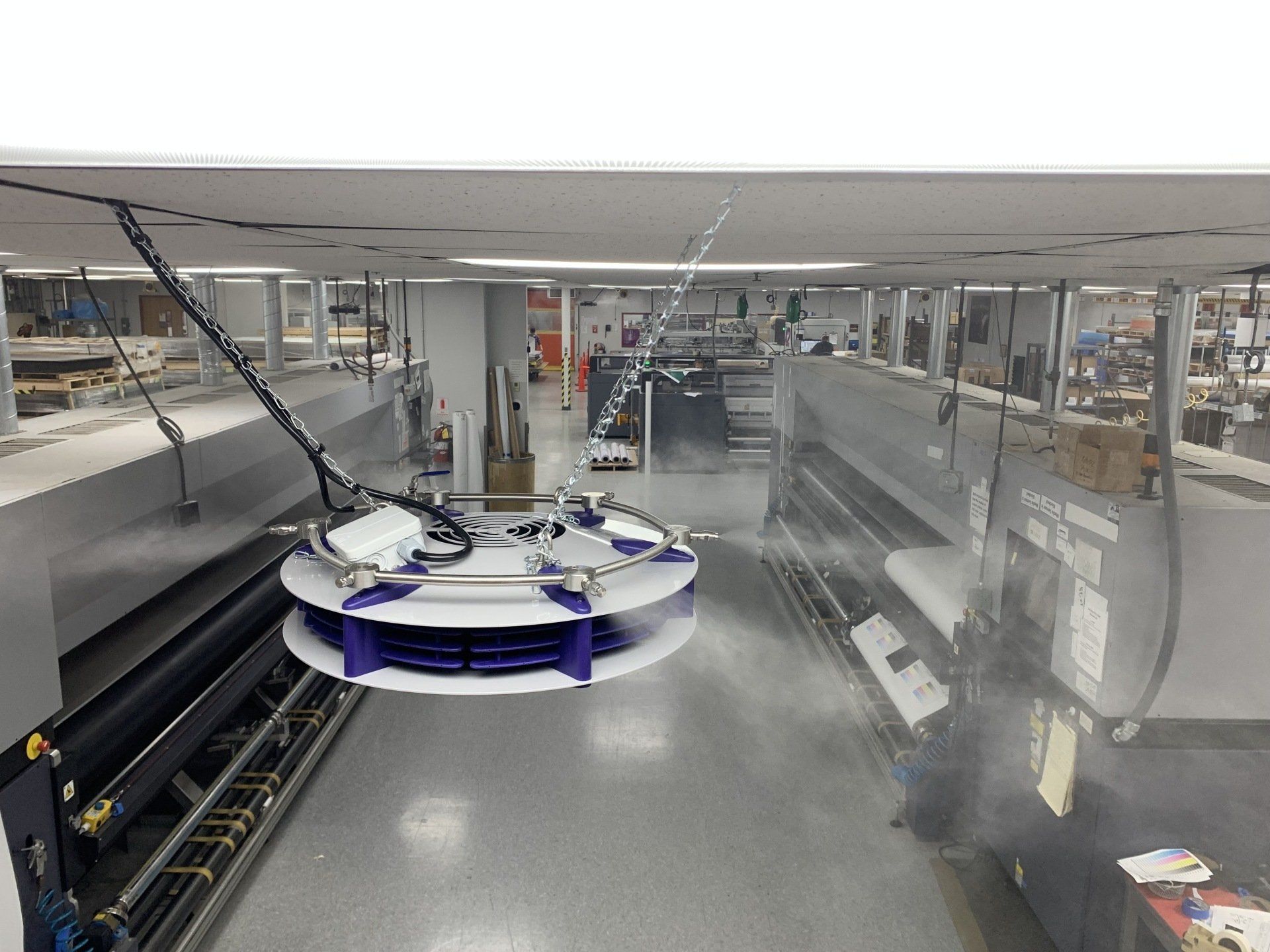

Printing & Substrate

Maintaining a perfect environment with controlled humidity

(40-60%RH) is crucial for the optimal operation of your press and ensures to achieve the designed press speed and print quality.

Avoiding low humidity or dry environments are essential for the operation of printers, presses and paper production itself. If you are in the printing industry or related to it, many equipment manufacturers already specify the operating conditions for their equipment (40-60% RH). To guarantee the best output, having an optimal humidity will avoid the inverse; costly dry conditions which will cost downtime or even damage to your equipment.

With increased printing speeds and quality demands, creating the perfect conditions for the printing industry is essential for a profitable operation. Whether it is an offset, flexographic or digital printing process, the right humidity matters to ensure the perfect print.