Air humidity as a quality factor

Merlin Technology

Air humidity as a quality factor

Wherever water-based paints are used, high-quality air humidification systems have an extremely positive effect on people, materials and machines. The following article reveals what really matters.

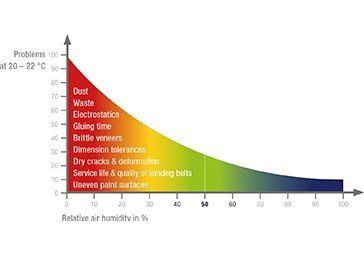

The problems are best known in the car, aircraft and their supplier industries: Excessively dry air indoors causes dust, electrostatic charges as well as expensive rejects and annoying rework in surface technology. Due to the poor climatic conditions, the surface quality of the painted parts suffers and there is a delicate additional demand for material. At the same time, the performance of the workforce can fall noticeably. But there are other ways.

Efficient solutions

High-quality air humidification systems turn the tables completely and result in higher quality, productivity and energy efficiency. “The relative air humidity in the room is an essential success criterion and should lie constantly in the defined range, which often moves between 40 and 65% relative humidity. This is not only good for the surfaces, but also for the vitality of the employees,” points out Franz Schrems. The project manager for surface technology at the Upper Austrian air humidification specialist Merlin Technology talks plainly: “If there are problems in surface technology in winter that you don't have in summer, it's down to the “air humidity”.

Great differences

Several criteria play a role in choosing the right air humidification system. The differences in the market are considerable, especially in terms of efficiency and effectiveness. For example, Merlin Technology's patented Orbit Wing® high-pressure duct humidification system saves up to 95% energy compared with conventional electric steam generators. The system can be integrated into any existing or new ventilation and air conditioning system and achieves water and energy efficiency of 98 percent. “Only 2.5 watts of energy are used to generate 1 kilogram of moisture. Conventional electric steam generators require up to 750 watts to do this,” remarks Schrems, who points out another crucial criterion.

“The exact and individual regulation of the humidity in the individual zones is essential for optimum results in surface technology. In this respect, the combination of stage and pressure control is pioneering for the market. It reliably prevents over-humidification and guarantees a constant humidity value,” says the senior Merlin technician from experience.

Less space required

Modern systems humidify the air directly in the duct. The spatial requirements for this are challenging. Since aerosols require at least about 1.5 seconds evaporation time, an evaporation distance of almost four metres would be required at an air speed of 2.5 m/s in the duct. In many cases, this required space does not exist. Up to now, this problem could mostly only be solved with energy-intensive and cleaning-intensive systems. But now there is a new, innovative solution. With the Orbit Wing® System from Merlin Technology, patented wing elements ensure a defined turbulence at the tear-off edge. The aerosols fly in a circle and cover a longer airborne range at a shorter distance. The evaporation distance reduced by 50 percent saves a lot of space and is considered to be particularly hygienic

Hygiene in focus

Hygiene management should be given particular attention when selecting the air humidification system. Those who want to do something good for the environment rely on oil and maintenance-free hydraulic pumps that are ideally frequency-controlled and water-saving. Typical hygiene features include continuous water-bearing components made of corrosion-resistant stainless steel or food-safe plastics. Leading manufacturers also offer hygiene interval circuits and individual interfaces to building control systems.

Constant surface tension

A constant surface tension is achieved with constant air humidity. “The problems are diminishing and the yields are rising. High-quality air humidification systems thus also increase production and quality safety. In the automotive industry, they make a valuable contribution to possible zero runs,” says Schrems. To meet specific requirements on site, modular air humidification systems are recommended. Despite their flexibility, they are easy to install. The maintenance effort for modern systems is manageable and is even close to zero for some providers. We also recommend sophisticated air humidification systems that guarantee simple operation with all their features.

Less sick leave, more quality

High-quality air humidification systems reduce dust by up to 80% and significantly improve the indoor climatic conditions. This results in increased production speed, improved and consistent surface quality and less sick leave. In addition to this, air humidity influences people's perception of heat. If the room air is too dry, it must be warmed by about 1 to 2° C so that the person feels just as comfortable as with optimal humidity*). This is reflected considerably in the energy costs. And if you feel good, you can achieve more.